صنایع فلزی و معدنی

صنایع فلزی ( فولاد، مس، آلومینیوم و ... ) و صنایع فعال در حوزه معدن

مشاهده بروشور

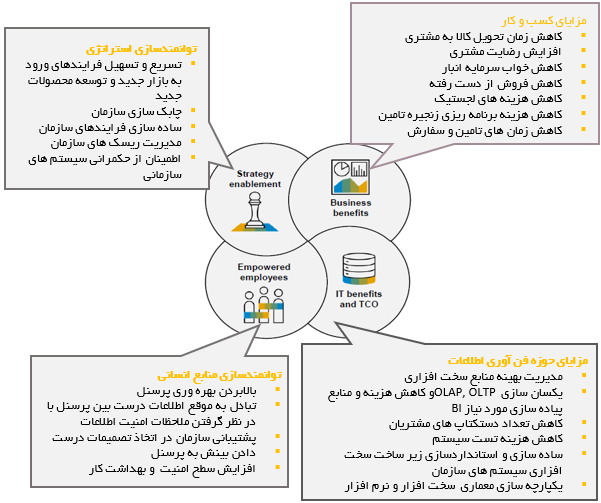

بخش عمده ای از شرکت های بزرگ فعال دنیا در حوزه فولاد و صنایع فلزی از راهکار SAP-ERP بهره مند هستند. لذا سیستم SAP-ERP به واسطه نمونه های پیاده سازی متعدد در دنیا از الگوهای برتر کسب و کار غنی در این حوزه برخوردار می باشد. باتوجه به این که صنایع فولادی و فلزی از جمله صنایع مهم و بررگ کشور ایران محسوب می شوند استقرار سیستم SAP-ERP در این شرکت ها فرصت مناسبی برای برخورداری از تجربیات موفق شرکت های بزرگ مشابه در دنیا را برای آنها فراهم می سازد . شرکت سامه آرا درتلاش است که این تجربیات موفق را در صنعت فولاد و صنایع فلزی کشور در قالب پروژه استقرار SAP-ERP منتقل نماید که از آن جمله می توان به مجتمع صنعتی فولاد پاسارگاد اشاره نمود .

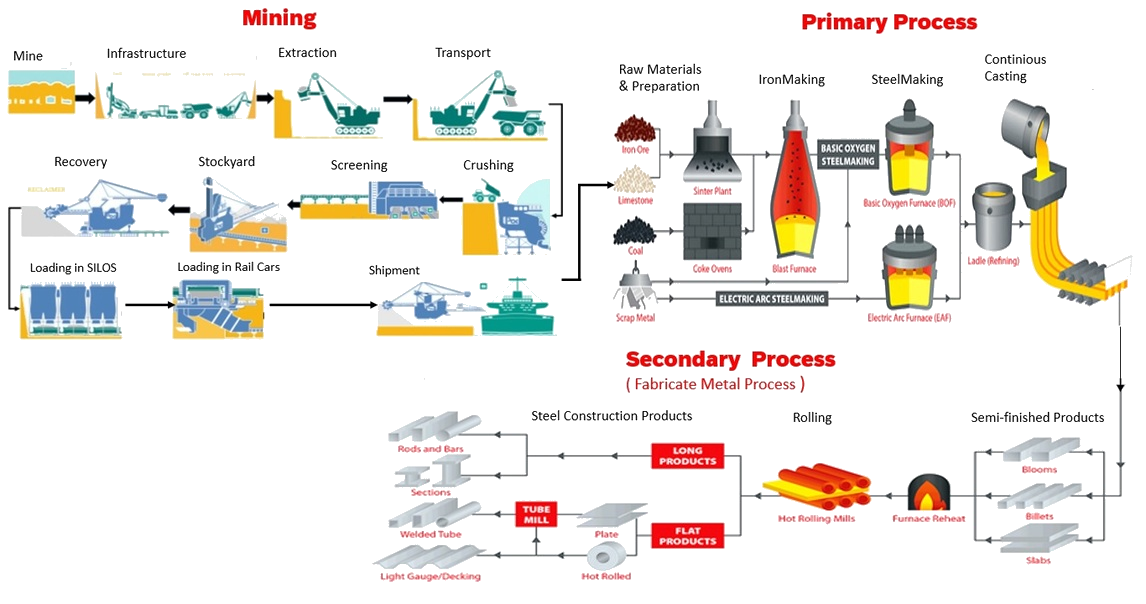

فرآیندهای اصلی در زنجیره ارزش صنایع فلزی :

-

ورود به بازار ( توسعه محصولات جدید و تحلیل داده های چرخه عمر محصولات )

In the Mill Products industries there are some segments where speed of new product development and introduction means the difference in meeting customer demands and obtaining profitable orders. Ongoing customer retention and satisfaction is improved with shorter time to market cycles. Tight integration with suppliers is a key component enabling rapid response.

-

برنامه ریزی زنجیره تأمین

Supply chain planning in mill industries is extremely important in running an optimal business. Mill companies often provide products that are produced with long lead times prior to final consumer consumption. Collaborative input from all partners in the supply chain is a key ingredient to maximizing the allocation of human, production and delivery resources.

-

منبع یابی و تأمین

Procurement maximizes the return on relationships with all suppliers across all categories of spend. It covers the full supply cycle, from strategic sourcing to operational procurement and supplier enabling- leveraging consolidated content and master data. Benefits that can be realized include optimization of supplier selection, compression of cycle times, and creation of sourcing and procurement strategies to reduce administrative effort. -

تولید و مدیریت انبار

A well executed supply chain has the potential to have a great impact on the performance of the company both in terms of profitability and customer satisfaction. Based on an accurate collaborative demand plan, a coordinated and flexible execution will enable companies to react quickly to changes in demand or to problems in production while still maintaining high levels of customer service.

-

مدیریت ارتباط با مشتری

Customer satisfaction is influenced by many factors including response time to queries, product delivery performance and quality, and complaint handling processes. Knowledge about the customer enables quick and appropriate responses that create satisfied customers who find it easy to do business with their supplier

-

تعمیرات و نگهداری

.

-

مدیریت کیفیت و بهداشت صنعتی و محیطی

Quality Management in the mill products industry is no longer simply about integrating internal business processes. The focus has shifted to the employees and their dedication and skills, while efficient business processes remain critical factors for success. The fast, direct exchange of internal and external information and a global information flow are essential for staying ahead of the competition.

The QM solution enables mill products companies to manage and assure product quality, monitor and improve quality standards and document quality compliance for subsequent audits.

The Compliance solution offers a wide range of functionalities to fulfill legislative requirements in certain areas like environment, health & safety and global trade processing